CCUS: Intermodal, safe, scalable

Save the date:

March 23rd, 2026 at the Port of Esbjerg

CO 2.0 Infrastructure - Project Launch Event

DecarbonICE at

Carbon Capture Journal

March 5th 2026

Why CCUS?

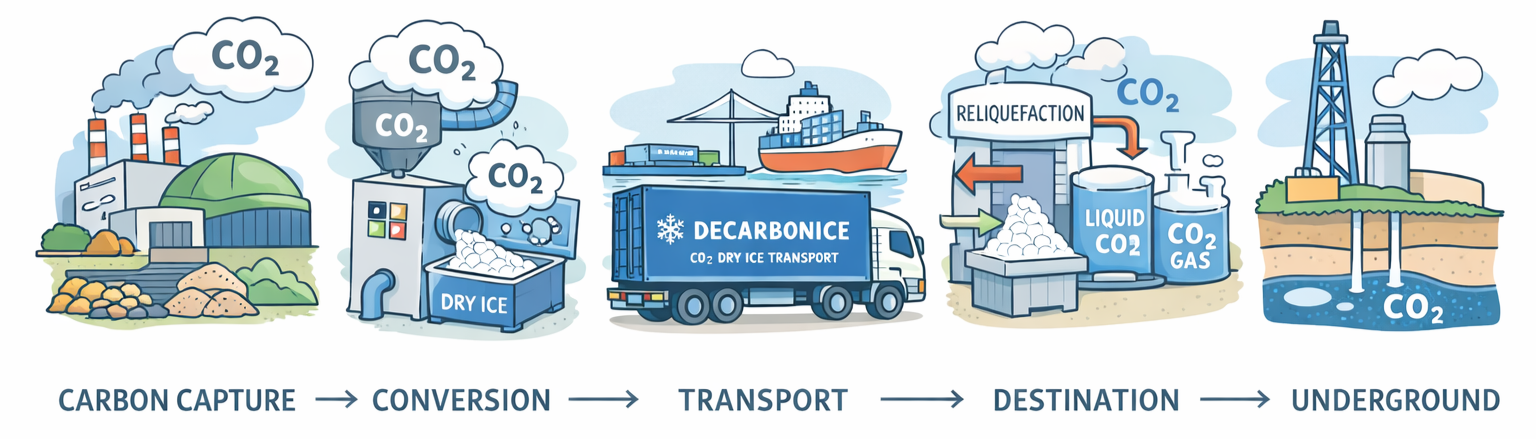

Carbon Capture, Utilization and Storage (CCUS) is essential for cutting hard-to-abate CO₂ emissions, but transporting CO₂ safely, affordably, and at scale remains a major bottleneck for many projects. Traditional pipelines or pressurized tank solutions are expensive and slow to deploy.

DecarbonICE overcomes this challenge with a scalable CO₂ transport solution that moves captured CO₂ as dry ice using standard container logistics, making the transition from capture to storage or utilization simpler, safer, and more cost-effective.

The DecarbonICE..

-

DecarbonICE was founded by experts in CCUS, supply-chain, energy and IT. The team combines deep technical expertise with innovative mindset.

-

DecarbonICE provides safe, efficient, and scalable transport solutions for captured CO₂ in the form of dry ice. Our approach enables flexible and reliable carbon logistics, supporting the deployment of CCUS across industries and regions.

-

DecarbonICE collaborates with emitters, technology providers, logistics operators, and storage developers across the CCUS value chain. Together, we enable integrated, end-to-end carbon transport solutions that connect capture sites to utilization and permanent storage.

Why now?

Climate change demands urgent action to cut CO₂ emissions.

Industries need sustainable, efficient CO₂ management solutions.

Current CO₂ transport options are costly, inefficient, and pose safety challenges.

DecarbonICE delivers a smarter, safer, and more cost-effective way to transport CO₂.

Join the future of CO₂ transport today.

Simple, safe and scalable CO₂ transportation.

DecarbonICE is revolutionizing CO₂ transport with a cost-efficient, safe, and scalable solution. Our patented technology enables CO₂ to be transported in its natural solid form - dry ice - at ambient pressure. By leveraging the global container transport network, we eliminate the need for expensive and complex pipelines or cryogenic tanks. Using our specialized DecarbonICE container, CO₂ can be efficiently transported within existing dry ice logistics. Once delivered, our reliquefying unit seamlessly converts dry ice back into liquid or gas, meeting any specifications required for end-use applications. DecarbonICE is reshaping CO₂ transport and storage, cutting costs, enhancing safety, and simplifying handling. It's time for a paradigm shift in the CO₂ value chain — probably the coolest way to cut CO₂.

Ideal for Biogas

DecarbonICE’s dry-ice based CO₂ transport solution is ideal for biogas plants, where capture volumes are typically smaller and decentralized. The modular, containerized system enables flexible, cost-efficient transport without the need for large-scale pipeline infrastructure.

Contact us to learn more.

Supported by

Industry partners